-

-

Regina Industrial Solutions

Regina Industrial Solutions

World leading portfolioof Standard & Special Chains

and application componentsRegina Industrial Solutions

World leading portfolioof Standard & Special Chains and application components

-

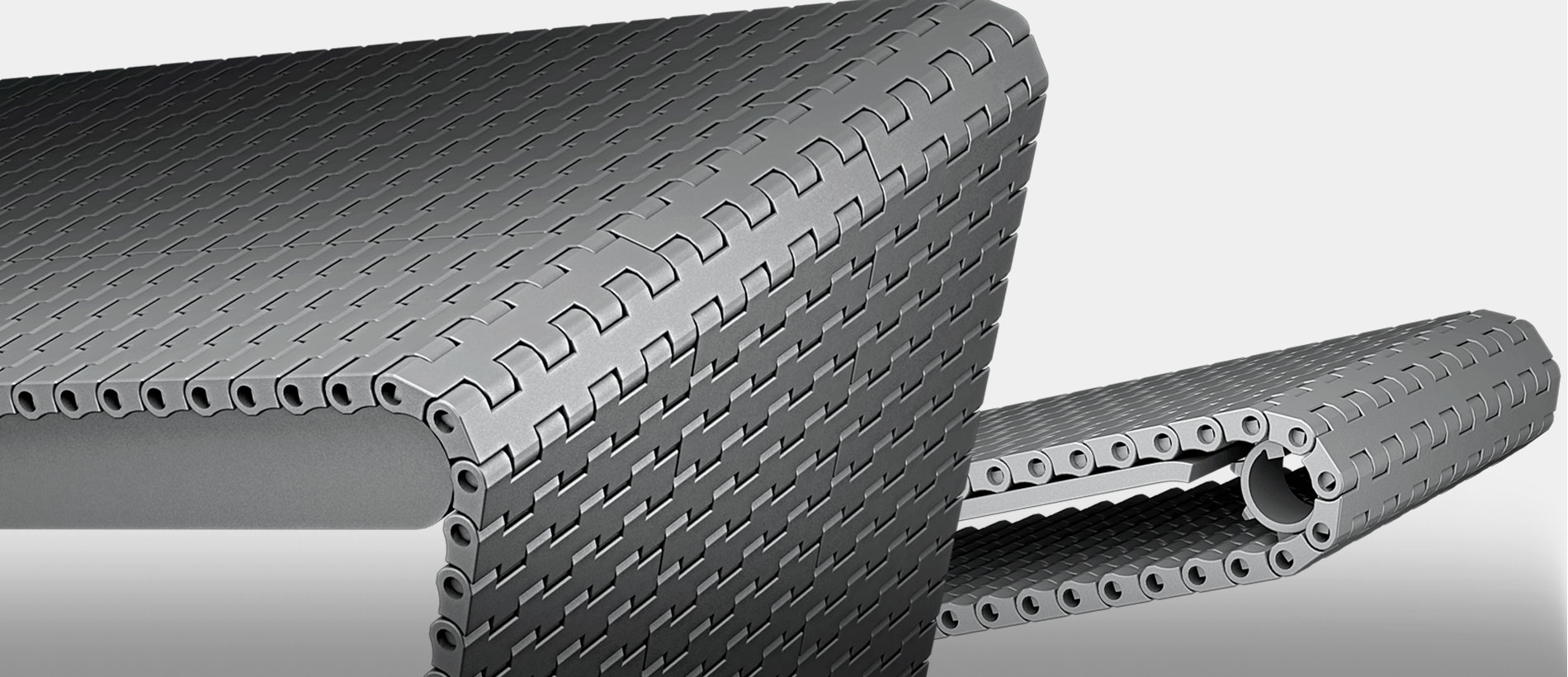

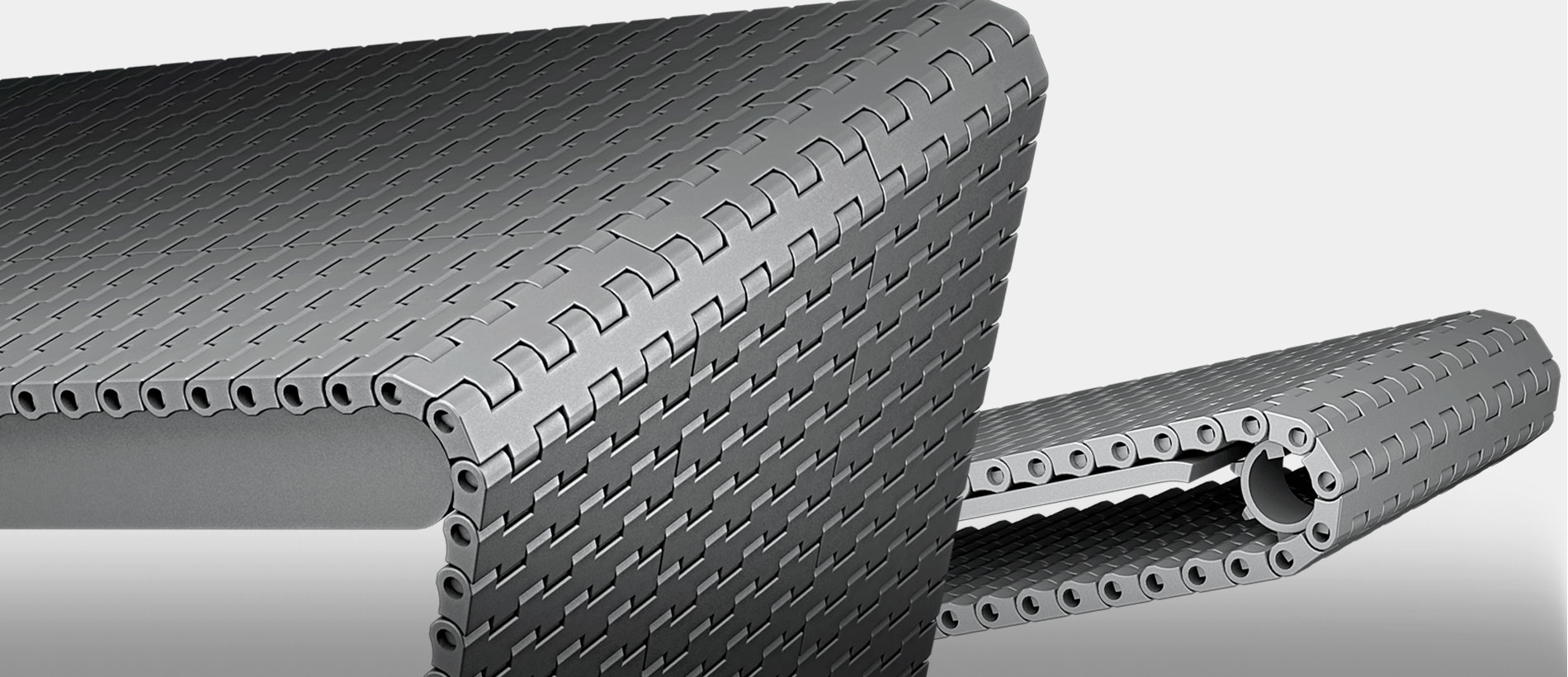

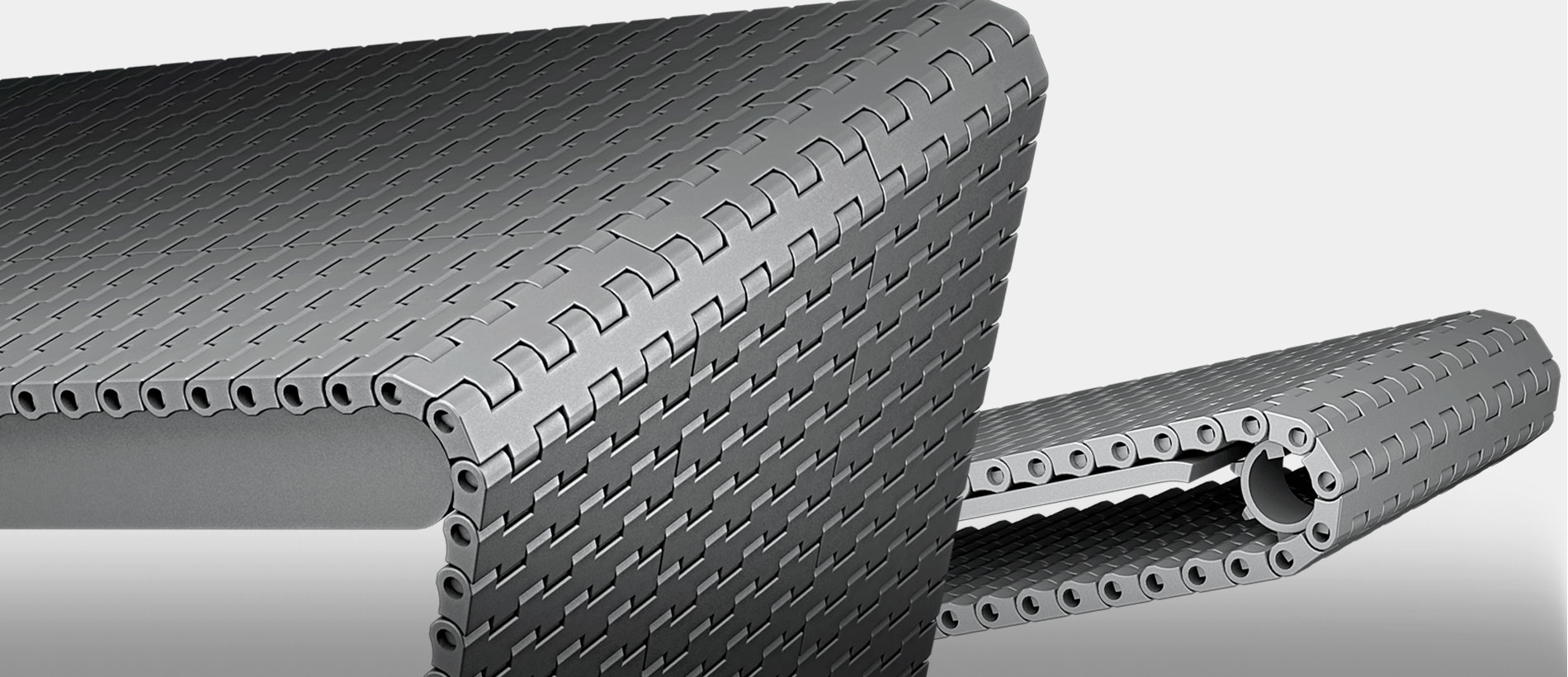

Matveyor

Matveyor

Modular Belts and ComponentsModular Belts and

ComponentsMatveyor

Modular Belts and Components

-

e-F.A.S.T.

Dry running material for ultimate high speed bottling applications

-

Jorge Martín # 89

Pramac Racing

-

HPE

The high performance endurance chain for motorcycles

-

Proud supplier of all

World Championship MotoE teams